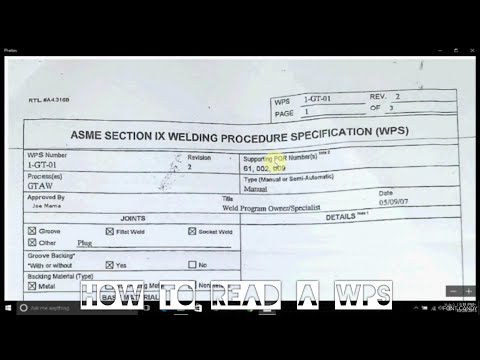

P>What's up, waters? Paul here, welcome to another episode of Adventures in Welding. Today, we are going to be talking about WPS or Welder Welding Procedure Specification. I have a WPS here, this one is from ASME, the American Society of Mechanical Engineers. It is a three-page WPS and we're going to go over it. I'm going to show you a little bit about how to read WPS and what the sections are and what everything means. Alright, here's our WPS that we're going to look at today. This is a number one GTO one from ASME, the American Society of Mechanical Engineers. It is supported by these PQRS. PQRS are the ance qualification records. These are the welds that have been done and been tested to support this process. Here is GT WR, the TIG process. It has been approved by, in this case, Joe Mama, who is the weld program owner and specialist. Now, the types of joints applicable here are groove weld, fillet weld, socket weld, and plug weld, with or without backing. Yes, that does not make much sense. I should say, with or without braces. Yes, a backing material is metal. Here, we have our base materials P number and group. Now, our base metal thickness range for groove welds without post weld heat treatment is 1/16 inch to eight inches. No impacts, see note three, and we'll get to that when we get to the third page. Groove welds with post weld heat treatment are 3/16 to 1.7 to 8, no impacts, unlimited thickness. For filler welds, our deposited weld metal thickness range is an inch and a half without post weld heat treatment and 0.56 inches with post weld heat treatment. Again, unlimited for fillet welds. Pipe diameters long applicable here, and our...

Award-winning PDF software

Welding procedure specification PDF Form: What You Should Know

Figure 5.14—Warping Procedure Diagram Figure 5.14—Warping Procedure Diagram. WELDING PROCEDURE SPECIFICATION (WPS). 3) If you are welding an item for which a pre-welding qualification has been pre-approved. Figure 5.15—Warping Procedure Diagram Figure 5.15—Warping Procedure Diagram. WELDING PROCEDURE SPECIFICATION (WPS). 4) If you are welding a single piece item. Figure 5.16—Warping Procedure Diagram Figure 5.16—Warping Procedure Diagram. WELDING PROCEDURE SPECIFICATION (WPS). 5) If a project requires that you complete a pre-welding qualification prior to the start of work. Figure 5.17—Warping Procedure Diagram Figure 5.17—Warping Procedure Diagram. WELDING PROCEDURE SPECIFICATION (WPS). 6) If your qualification tests are performed using a machine other than a CNC and the pre-welding qualification was obtained using an automated welding process (not including a SEQ machine). Figure 5.18—Warping Procedure Diagram Figure 5.18—Warping Procedure Diagram. WELDING PROCEDURE SPECIFICATION (WPS). 7) If you plan on welding a piece that requires a safety-related safety clearance to a weld joint or other item. Figure 5.19—Warping Procedure Diagram Figure 5.19—Warping Procedure Diagram. WELDING PROCEDURE SPECIFICATION (WPS). 8) If you plan on welding a piece that is designed or constructed in such a way that the item may move. Figure 5.20—Warping Procedure Diagram Figure 5.20—Warping Procedure Diagram. WELDING PROCEDURE SPECIFICATION (WPS). 9) If all other eligibility requirements have been met, proceed to page 2 of the welding procedure. Figure 5.21—Warping Procedure Diagram, Welding Processes A -A Figure 5.21—Warping Procedure Diagram, Welding Processes A -A. 10) Ensure the project has been approved as a Project of Concern according to SD 7.1.1.3, SD 7.1.1.

online solutions help you to manage your record administration along with raise the efficiency of the workflows. Stick to the fast guide to do Asme Qw 482 Form, steer clear of blunders along with furnish it in a timely manner:

How to complete any Asme Qw 482 Form online: - On the site with all the document, click on Begin immediately along with complete for the editor.

- Use your indications to submit established track record areas.

- Add your own info and speak to data.

- Make sure that you enter correct details and numbers throughout suitable areas.

- Very carefully confirm the content of the form as well as grammar along with punctuational.

- Navigate to Support area when you have questions or perhaps handle our assistance team.

- Place an electronic digital unique in your Asme Qw 482 Form by using Sign Device.

- After the form is fully gone, media Completed.

- Deliver the particular prepared document by way of electronic mail or facsimile, art print it out or perhaps reduce the gadget.

PDF editor permits you to help make changes to your Asme Qw 482 Form from the internet connected gadget, personalize it based on your requirements, indicator this in electronic format and also disperse differently.

Video instructions and help with filling out and completing Welding procedure specification PDF