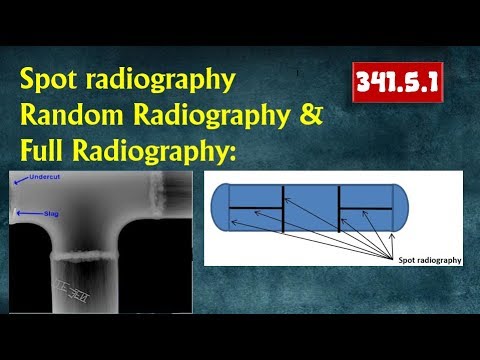

This video is only an attempt to familiarize the respective users with the various codes and standards rules requirements and guidelines. Users shall fully read and understand the references wherever made in this video from the licensed or genuine copies, and then only consider the same for specifying, discussing, and/or applying wherever required. The dialogues, descriptions, and intent of the video are virtuously personal and in no way tend to undermine, modify, replace, or substitute the intent definitions and descriptions made in the referenced codes and standards. Music hello mentor. Hello user, on terms used for examination of wealth. Okay, what's that? I want to understand what actually is meant by full examination, spot examination, and random examination. It's not so confusing, let me explain it. Full radiography would require that every inch of weld length be radiographed. For big equipments, like towers and tanks, this would mean hundreds of shots and a long process to complete. Though this is tedious, it assures that there are no flaws that will cause a failure later. Understand? This was simple. What about spot examination? Spot radiography, on the other hand, would mean radiography of a percentage, say 1%, of the total weld length at various spots, particularly critical spots like junctions. It is done to get radiography of a significant percentage of total weld length. So does it mean that spot radiography is an aid to quality control and is like a sampling plan where the code does not require a weld to undergo full 100% radiography? Yes, it does. Typically, if the equipment or piping is very critical, then codes, standards, and guidelines would require you to do full radiography. If it happens to be a water tank, spot radiography is generally good and hence it means 10% spot radiography is 10% of total...

Award-winning PDF software

Asme sec v 2017-2025 free download Form: What You Should Know

Item 2. Electrical and Pressure Vessels — ASHE Section VI.3 — Item 4. Electrical and Pressure Vessels — ASHE Section VI.3. 1, 4, 10.3, 12.3. 2, 13.3. 8, Item 5. Electrical and Pressure Vessels — ASHE Section VII.3. Item 10. Electrical and Pressure Vessels — ASHE Section VI.5. 10.4. 10.5.2. 12.5.8, 13.6.14. 15.2.14, 17.6.22, 22.9.20, 25.13.10. Item 10.1. Electrical and Pressure Vessels — ASHE Section VI.5 (1) — Item 10.1.1. Electrical and Pressure Vessels, Section VI.5.7, Section VI.5.8, Section VI.5.9, Section VI.5.11, Section VI.5.12. Item 11. Electrical and Pressure Vessels — ASHE Section VI.5.14, Section VI.6 — Item 12. Electrical and Pressure Vessels — ASHE Section VI.6. 3; Item 13. Electrical and Pressure Vessels — ASHE Section VI.8. 1; Item 14. Electrical and Pressure Vessels — ASHE Section VI.9. 4; Item 15. Electric Steam, Electric Fireplace, Fireplace, Fireplace, Gas Electric and Electric Hot Water Heater- ASHE Section 16.2.3.3. 16.3.2. 17.2.7. 3. 17.2.11.2. 24.3.9. 12, 12.1.6., 12.2.3 .12., 12.3.2., 24.3.9. Item 16,17 and Item 14 of ASHE Section 17.2.5.12. 19.6.11.3 Item 3,9. Item 18. Item 15.4.6., Item 25. Item 9.10.12.1. 9.12.4. Item 24. 25.7.2.4., 25.7.2.5.

online solutions help you to manage your record administration along with raise the efficiency of the workflows. Stick to the fast guide to do Asme Qw 482 Form, steer clear of blunders along with furnish it in a timely manner:

How to complete any Asme Qw 482 Form online: - On the site with all the document, click on Begin immediately along with complete for the editor.

- Use your indications to submit established track record areas.

- Add your own info and speak to data.

- Make sure that you enter correct details and numbers throughout suitable areas.

- Very carefully confirm the content of the form as well as grammar along with punctuational.

- Navigate to Support area when you have questions or perhaps handle our assistance team.

- Place an electronic digital unique in your Asme Qw 482 Form by using Sign Device.

- After the form is fully gone, media Completed.

- Deliver the particular prepared document by way of electronic mail or facsimile, art print it out or perhaps reduce the gadget.

PDF editor permits you to help make changes to your Asme Qw 482 Form from the internet connected gadget, personalize it based on your requirements, indicator this in electronic format and also disperse differently.

Video instructions and help with filling out and completing Asme sec v 2017-2025 free download